- Testing Redefined

- +91 81081 23468

- admin@syselec.net

SOLUTIONS

1. Introduction

1.1 Purpose

This Functional Requirements Specification (FRS) defines the functional and non-functional requirements, architecture, interfaces, and constraints for the FMEA Executive software used for DFMEA/PFMEA authoring, review, risk assessment (S–O–D, RPN/AP), actions tracking, and reporting.

1.2 Background

The organization conducts FMEA activities across multiple sites and requires a consistent, auditable system to author, approve, baseline, and report FMEAs. This document also responds to the formal query requesting the list of machines, frameworks, languages, SDLC, databases, and hardware used.

1.3 Definitions & Acronyms

- FMEA: Failure Mode and Effects Analysis

- DFMEA/PFMEA: Design/Process FMEA

- RPN: Risk Priority Number (S×O×D)

- AP: Action Priority (per AIAG–VDA)

- S/O/D: Severity/Occurrence/Detection

- FRS/SRS: Functional/Software Requirements Specification

2. Stakeholders & User Roles

- FMEA Author/Engineer: Creates and edits FMEAs, assigns actions.

- Process Owner: Owns PFMEAs for assigned lines.

- Quality Manager: Governance, templates, libraries, audits, reports.

- Admin/IT: User management, configuration, backups, integrations.

3. System Overview

FMEA Executive is a .NET application with a configurable backend that supports:

- Central SQL Server database (primary) or Microsoft Access database (for small/offline deployments).

- Option for cloud-hosted SQL Server (AWS RDS/EC2) or on-prem SQL Server.

- Desktop client packaged as Windows application (.NET 6/7+, C#); option for Windows Forms or WPF UI based on deployment decision.

4. Architecture

4.1 Logical Architecture

- Presentation Layer (Desktop .NET): FMEA editor grids, dashboards, action center, report designer.

- Application Layer: Business services for scoring (S/O/D, RPN/AP), libraries (functions, failure modes, causes, controls), workflow (draft → review → approve → baseline), notifications, validation.

- Data Access Layer: ORM/ADO.NET repository pattern for SQL Server/Access.

- Data Layer: SQL Server (preferred); Access for single-site or offline scenarios.

4.2 Deployment Architecture (Options)

A. Cloud-Hosted (Recommended)

- Windows desktop clients → HTTPS → App Service/API (optional) → AWS-hosted SQL Server (RDS/EC2).

- Secure access via VPN/PrivateLink or IP allowlist.

- Backups via RDS automated snapshots; DR with cross-region snapshot copy.

B. On-Premises

- Windows desktop clients on → On-premise software liscence

- Backups to in-house backup servers.

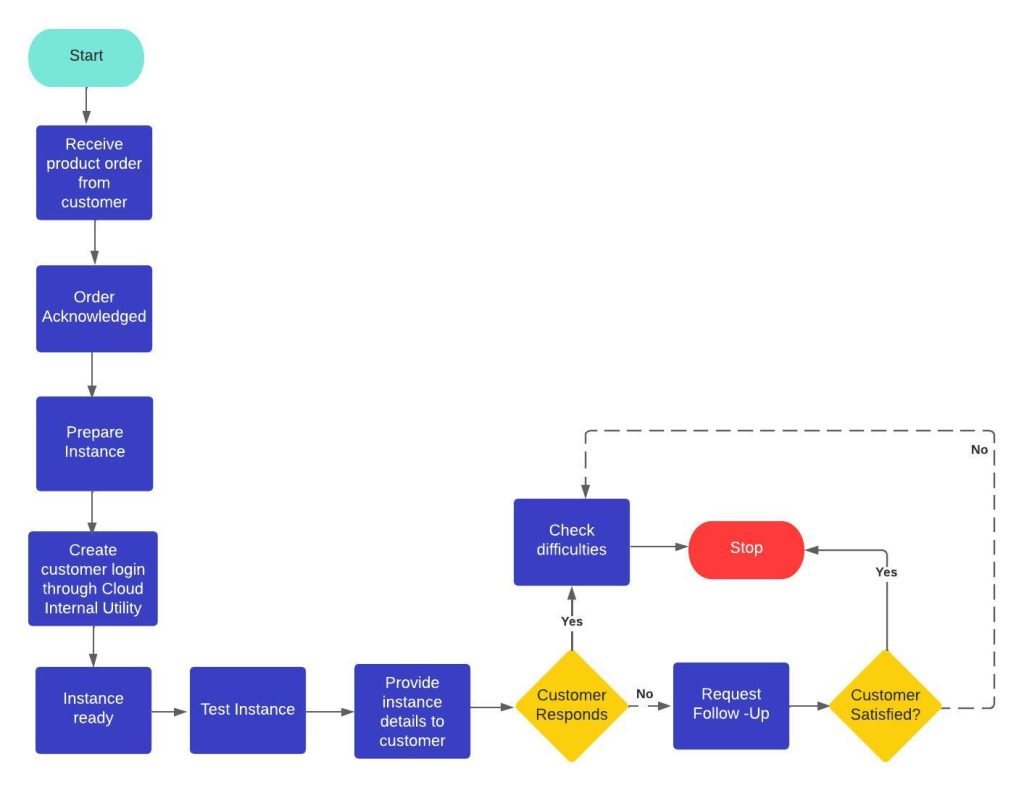

Cloud-Hosted Solution Flow Diagram

Cloud-Hosted Solution Flow Diagram

4.3 Technology Stack (FMEA Executive Only)

- Language: C#

- Framework: .NET 6/7+ (Windows Forms or WPF client)

- Databases: Microsoft SQL Server (primary); Microsoft Access (optional/small deployments)

- Reporting: SSRS/Local RDLC reports; export to Excel/PDF

- Version Control (Artifacts & Config): Git (GitHub)

4.4 Hardware & Network

- Developer/Engineer Machines: i5/i7 or Ryzen 5/7, 8–16 GB RAM, 512 GB+ SSD, Windows 10/11 Pro.

- Servers: Cloud-hosted on AWS (for hosted option) and/or in-house backup servers.

- Network: Firewalled, role-based access; VPN/IP allow list for cloud.

5. Functional Requirements

5.1 FMEA Authoring & Libraries

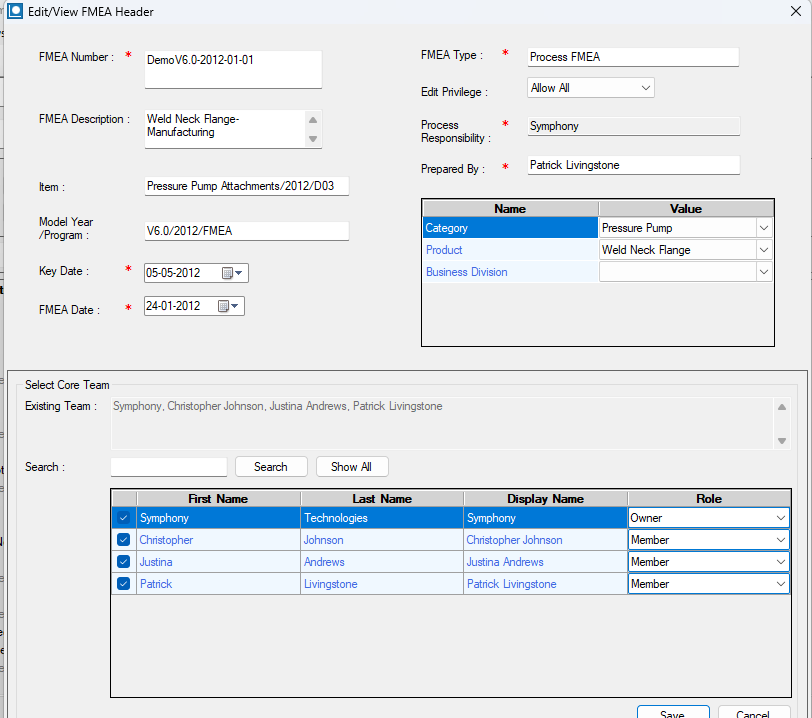

- FR-1: Create DFMEA and PFMEA projects with metadata (site, product, line, part no., revision, owner, dates).

- FR-2: Template-driven structure aligned to AIAG handbook (Function → Failure Mode → Effects → Severity; Causes → Occurrence; Controls → Detection).

- FR-3: Organization libraries for Functions, Failure Modes, Causes, Effects, Controls, Detection Methods, and ratings scales; configurable picklists and numbering.

- FR-4: Inline calculations of RPN and Action Priority (AP) based on configured tables.

- FR-5: Bulk edit, import from Excel/CSV, and copy-from-template; change tracking at row/cell level.

5.2 Workflow

- FR-6: States: Draft → In Review → Baselined; configurable reviewers/approvers.

- FR-7: E-signature with name, role, timestamp, and reason; immutable baseline snapshot.

- FR-8: Audit trail for create/update/delete with before–after values.

5.3 Actions & Mitigations

- FR-9: Create corrective/preventive actions with owner, due date, status, and evidence links.

- FR-10: Re-score S/O/D after action closure; maintain history of pre/post scores.

- FR-11: Action Center view with filters (overdue, due this week, by owner/site).

5.4 Risk & Reporting

- FR-12: Dashboards for top risks by Severity, RPN, and AP; heatmaps.

- FR-13: Standard reports: FMEA sheet, Action summary, Overdue actions, Change log, Baseline comparison.

- FR-14: Exports to Excel and PDF; configurable company letterhead on reports.

5.5 Data & Configuration

- FR-15: Multisite support with site-level numbering, calendars, and rating scales.

- FR-16: User/role management: Admin, Author, Reviewer, Approver, Viewer, Auditor.

- FR-17: Localization-ready (UI strings externalized); date/number formats per site.

- FR-18: Attachments (drawings, images, SPC charts) stored in DB or secure file store with references.

Data Model (High-Level)

- Entities: Project, FMEA (DFMEA/PFMEA), Function, Failure Mode, Effect, Cause, Control (Prevention/Detection), Rating (S/O/D), Action, User, Role, Attachment, Baseline, AuditLog, Template, LibraryItem.

- Keys: Natural keys for part/operation; surrogate keys (GUID/INT) for rows; version fields for baselining.

7. UI/UX Requirements

- Easy to use editor for FMEA rows with inline dropdowns for adding functions, failures etc.

- Ribbon/toolbar for common actions.

- Color cues for high Severity/AP; badges for overdue actions.

8. Validation Rules (Illustrative)

- Severity/Occurrence/Detection must be integers within configured scales (e.g., 1–10 or AIAG–VDA tables).

- At least one Prevention or Detection control per Cause before approval.

- No approval allowed if any action is Open past due date unless waiver recorded.

- Baseline requires all mandatory metadata filled and at least one reviewer approval.

9. Import/Export & Interoperability

- Import from legacy Excel/CSV templates; map columns to entities; preview before commit.

- Export full FMEA, Action List, and Change Log to Excel/PDF with letterhead.

- Optional Access DB sync for small sites; scheduled job to consolidate into SQL Server.

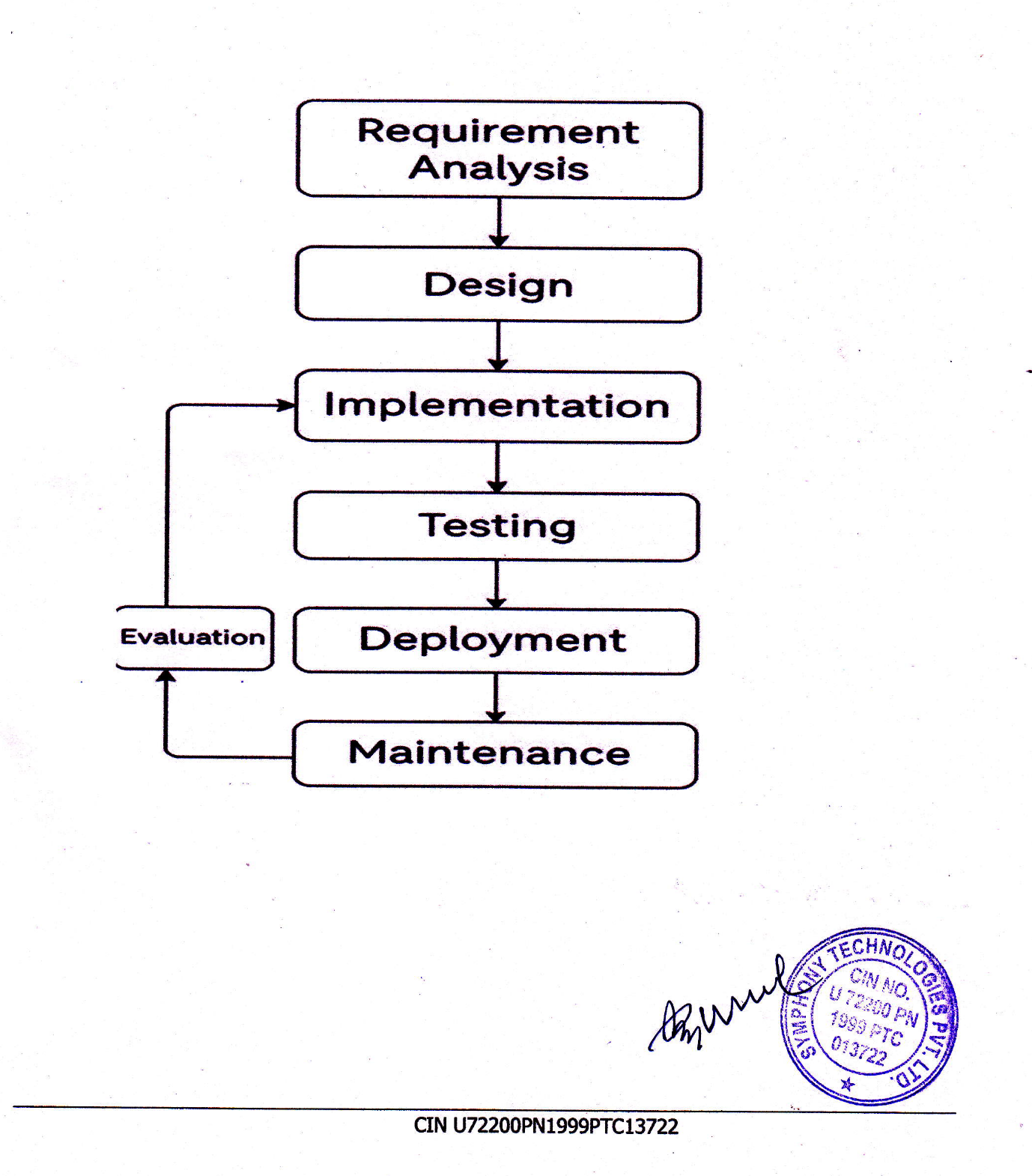

10. SDLC & Delivery

- Methodology: Agile (Scrum-based). Weekly sprint planning & retrospectives.

- Work Items: Managed in SharePoint (Loop components) or equivalent.

- Version Control: Git (GitHub/GitLab). Feature branching and PR reviews.

13. Environments & Installation

- Client: Windows 10/11 Pro; .NET Desktop Runtime.

- Database: If network Lisc SQL Server 2019/2022 (cloud or on-prem). For Access, provide .accdb files with schema migration scripts.

li>Configuration: App settings for DB connection

14. Compliance Mapping (AIAG–VDA)

- Structure matches AIAG–VDA forms; AP logic per handbook table; terminology configurable.

- Evidence: Baseline snapshot, audit trail, signatures, and change log reports.

15. Constraints & Assumptions

- Users have Windows domain accounts (if AD used) and required permissions.

- Network connectivity to SQL Server (or Access file share) is available.

- Company IT provides backups, antivirus, and patching per policy.

16. Traceability Matrix (Skeleton)

| Requirement ID | User Story / Feature | Design Ref | Test Case ID | Status |

|---|---|---|---|---|

| FR-1 | Create DFMEA/PFMEA | DES-UI-01 | TC-01 | |

| FR-6 | Review/Approve/Baseline | DES-WF-02 | TC-15 | |

| FR-12 | Risk Dashboards | DES-RPT-03 | TC-27 |

17. Appendices

- Appendix A: Machine & Tech Stack Response (FMEA Executive)

- Machines Used: High-performance development laptops and desktops (Intel i5/i7 or AMD Ryzen 5/7; 8GB+ RAM; 512GB/1TB SSD; Windows 10/11 Pro).

- Frameworks Utilized: .NET (Windows Forms or WPF) for client.

- Programming Languages: C#, SQL.

- SDLC: Agile (Scrum-based); weekly sprint planning & retrospectives; version control using Git (GitHub/GitLab); project management via SharePoint Loop components.

- Backend Database: Microsoft SQL Server (primary), Microsoft Access (optional/small deployments).

- Hardware (Servers/Networking): Development & testing servers (cloud-hosted on AWS); in-house backup servers; Git repositories; firewalled, access-controlled network infrastructure.

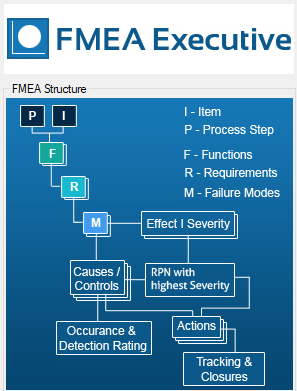

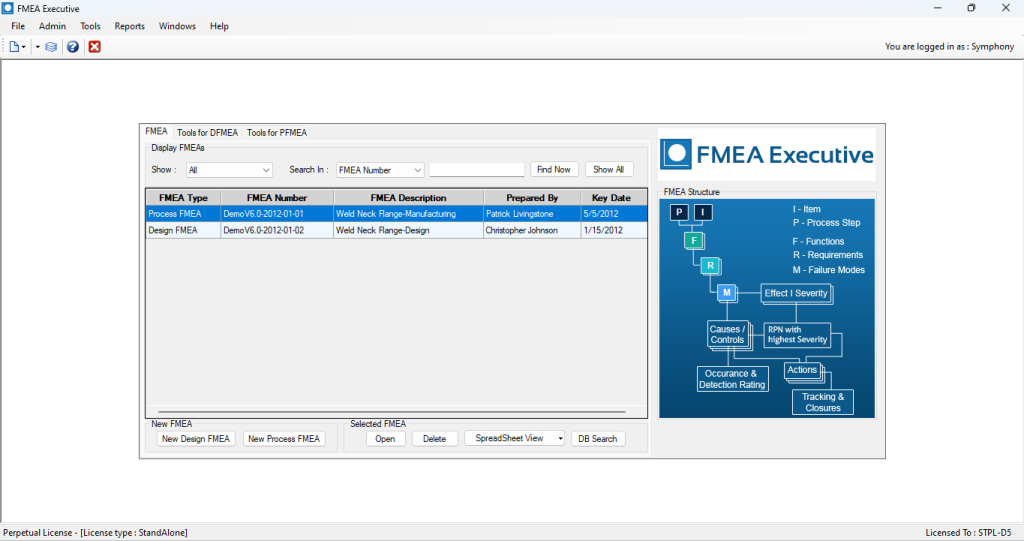

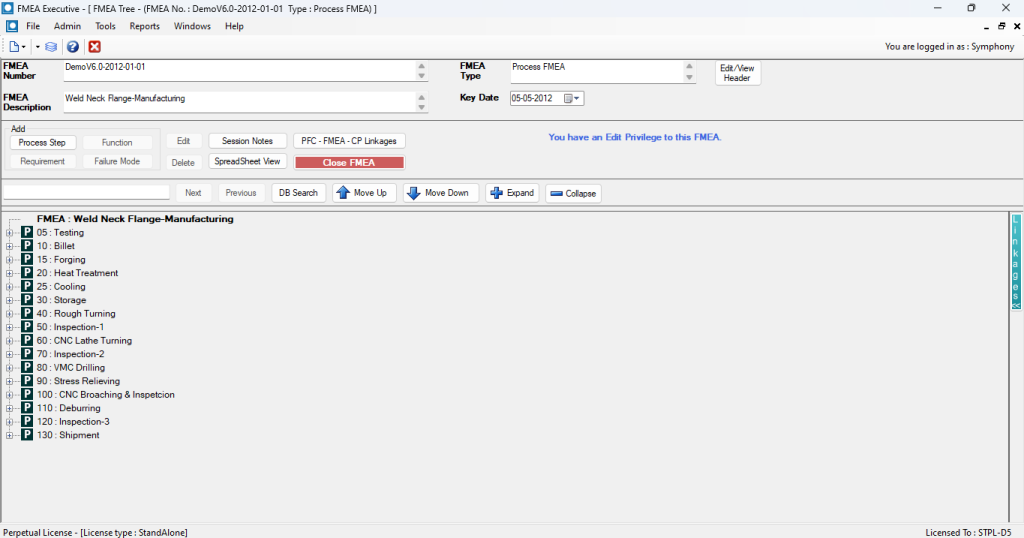

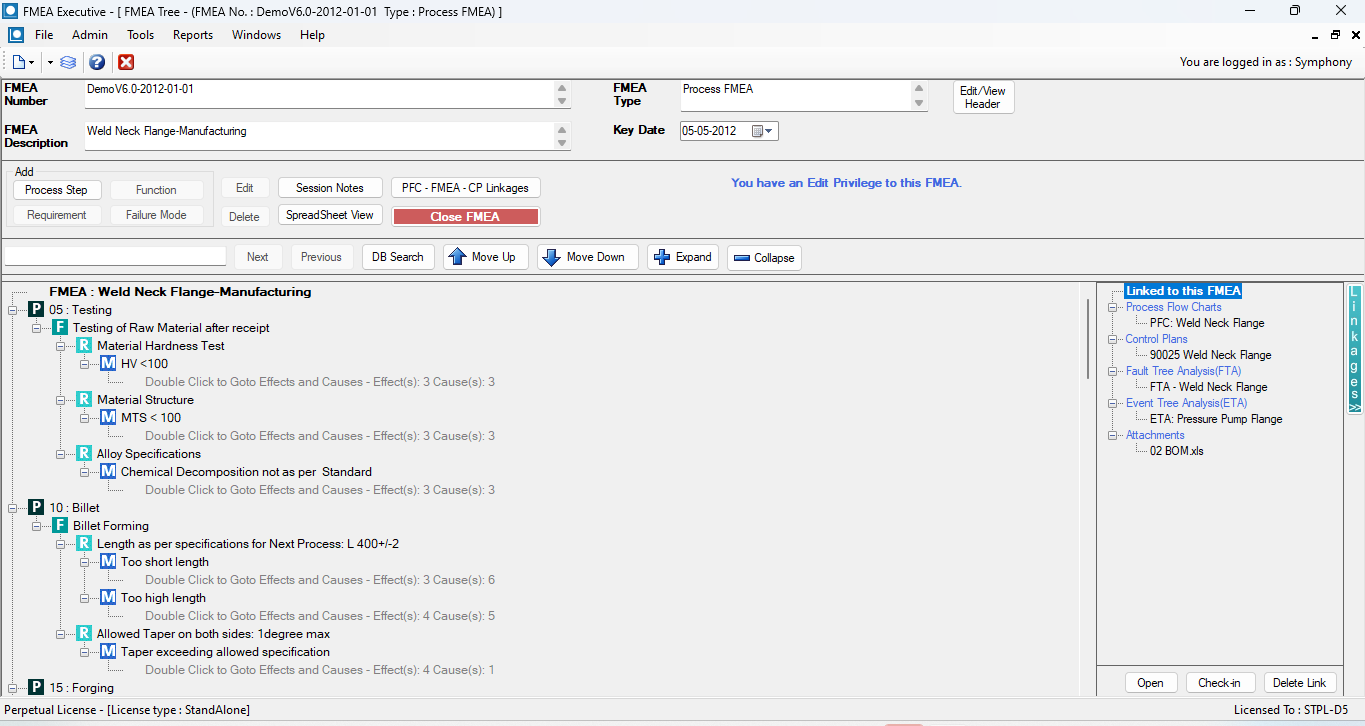

18. Sample Software Screens

FMEA Structure

FMEA created by user are listed as follows

Tree Structure For FMEA

EPC

For our Engineering Procurement Construction (EPC) business, we draw on our experience in the supply, installation, testing and commissioning, and providing after sales services in EHV cables, cable jointing up to 400kV, transformers, switchgear, autoreclosers & unmanned Substations.

List of Major Projects executed are as below:

| Sr No. | Customer Name | Project name | Region |

|---|---|---|---|

| 1 | ADANI ENTERPRISES LTD, Gujarat | ADANI_40MWP SOLLAR PROJECT | West |

| 2 | SIEMENS LTD | ADANI POWER LTD- HVDC MOHINDERGARH | North |

| 3 | SIEMENS LTD | ADANI POWER LTD-HVDC MUNDRA | North |

| 4 | ALSTOM T& D INDIA LTD | BIDCO- LALITPUR POWER GENRATION CO. | North |

| 5 | TECHNO ELECTRIC & ENGINEERING CO. LTD. | BSPTCL-Bihar State Power Holding Company Limited_Sonenagar/ Samstipur/ Musahari/ Kishanganj | East |

| 6 | ALSTOM – NOIDA | ESSAR – MAHAN THERMAL POWER STATION | North |

| 7 | ALSTOM – NOIDA | Essar Projects (India ) Ltd- Hazira | North |

| 8 | ABB LTD | Essar Steel Limited, Hazira Works | North |

| 9 | Sterling Wilson – Ahmedabad | GETCO-Bhachunda | West |

| 10 | SIEMENS LTD | GETCO-KOSAMBA | North |

| 11 | Stelmac – ltd | GETCO-Sanand | West |

| 12 | Stelmac – ltd | GETCO-VAV | West |

| 13 | ALSTOM PROJECTS INDIA LTD | GSECL- UTRAN 370MW CCPP | North |

| 14 | LARSEN & TOUBRO LTD | GSECL-375 MW DHUVARAN III GSECL CCPP PROJECT | Maharashtra |

| 15 | LARSEN & TOUBRO LTD, Mahrashtra | GSPC-PLQP | West |

| 16 | HIMACHAL PRADESH STATE ELECTRICITY BOARD LTD | HPSEB_HIMACHAL PRADESH STATE ELECTRICITY BOARD LTD | North |

| 17 | GE T&D Uttar pradesh | HPSEBL-Bhabhanagar | North |

| 18 | HARYANA VIDYUT PRASARAN NIGAM LTD | HVPNL-HO, Haryana | North |

| 19 | Siemens Limited – Jharkhand Office | JUSNL_132/33 kV, Jharkhand Urja Sancharan Nigam Ltd., s/s Pkg 1 | East |

| 20 | Technofab Engineering , Noida | JUSNL_Jharkhand Bokaro job no. 3593 JUSNL Project | North |

| 21 | Ram Kripal Singh Constructions Pvt. Ltd., Ranchi Jharkhand | JUSNL_Jharkhand Urja Sancharan Nigam Ltd, Giridhi | East |

| 22 | Gepdec Infratech Ltd., Noida | JUSNL_Jharkhand Urja Sancharan Nigam Ltd-JUSNL Transmission System In Jharkhand under PSDF | North |

| 23 | GSECL-Vadodara | KLTPS – Panandhro | West |

| 24 | ALSTOM BARODA,Gujarat | LOWER JURALA HEP | West |

| 25 | Karnataka Power Transmission Corp Ltd., Bangalore | 5 nos. Relay Test Kit | South |

| 26 | LARSEN & TOUBRO LTD, Maharashtra | MHN-PP & LQ | West |

| 27 | MSETCL- Mahrashtra | MSETCL- HO | West |

| 28 | MSETCL- VASHI | MSETCL_400KV KUDUS SUBSTATION | Maharashtra |

| 29 | MSETCL- Mahrashtra | MSETCL-HO | West |

| 30 | GE T&D – Mumbai | MSETCL-kudus | West |

| 31 | Bharat Heavy Electrical Limited, | NHPC LTD , PARBATI II HEP | North |

| 32 | ALSTOM INDIA LTD – VADODARA,Gujarat | NHPC LTD- HYDRO PROJECT- URI | West |

| 33 | Bharat Heavy Electrical Limited, | NHPC LTD, KISHANGANGA HE POWER PROJECT | North |

| 34 | Bharat Heavy Electrical Limited, | NHPC URI | North |

| 35 | NHPC Limited | NHPC_CHAMERA | North |

| 36 | Bharat Heavy Electrical Limited, | NHPC-CHAMERA | North |

| 37 | NHPC Limited | NHPC-SALAYA | North |

| 38 | NHPC, Teesta V, SIKKIM | NHPC-SF6 GAS ANALYZER | East |

| 39 | NHPC Limited | NHPC-Subansiri, | North |

| 40 | Bharat Heavy Electrical Limited, | NHPC-SUBHANSHI | North |

| 41 | NPCIL, Karnataka | NPCIL, Kaiga | South |

| 42 | NPCIL, Tirunevli | NPCIL, Kundakulam, | South |

| 43 | Techno Electricals Engg. Pvt. Ltd | NTPC-Kudgi | East |

| 44 | Techno Electricals Engg. Pvt. Ltd | NTPC-Meja | East |

| 45 | APTRANSCO, Hyderabad | APTRANSCO | South |

| 46 | Sime Darby Engineering Sdn Bhd (Malaysia) | ONGC_Oil and Natural Gas Corporation | Malaysia |

| 47 | Sime Darby Engineering Sdn Bhd (Malaysia) | ONGC_Oil and Natural Gas Corporation | Malaysia |

| 48 | Neccon | PGCIL – Assam & Meghalaya | East |

| 49 | Siemens | PGCIL – K L W (SVC Project), Ludhiana, Wampho and Kankroli | North |

| 50 | Siemens | PGCIL_Power Grid Corporation of India- K L W (SVC Project) | North |

| 51 | RongXin Power Electronic India Private Limited | PGCIL_Power Grid Corporation of India-Aurangabad | West |

| 52 | RongXin Power Electronic India Private Limited | PGCIL_Power Grid Corporation of India-Satara | West |

| 53 | ABB India Ltd | PGCIL_Power Transmission Corporation of Uttarakhand Limited | North |

| 54 | Madan contractor | PGCIL_Power Transmission Corporation of Uttarakhand Limited | North |

| 55 | Madan contractor | PGCIL_Power Transmission Corporation of Uttarakhand Limited | North |

| 56 | GE T &D | PGCIL-CKL2 Champa & Kurushetra | North |

| 57 | Bharat Heavy Electrical Limited, Noida | PGCIL-RP800_Raigarh & Pugalur Project Sites | North |

| 58 | GE T&D Jabalpur | Power Grid Corporation of India- Betul | North |

| 59 | Angelique International ltd | Power Grid Corporation of India, Patna | North |

| 60 | LNT – Andra pradesh | Power Grid Corporation of India-NP Kuntha | South |

| 61 | RongXin Power Electronic India Private Limited | Power Grid Corporation of India-Satna | North |

| 62 | Siemens Limited – Noida Office | STATCOM_Ranchi, JKRR, Flir Thermovision Camera | North |

| 63 | PGCIL-Vadodara | WR,ER,NR | West |

| 64 | TSTRANCO | TSTRANSCO | South |

We specialize in total turn-key electrical contracts catering to various segments like, EHV Cable Laying, Testing & Commissioning, Switchyards, Industrial & GIS, which involves Supply, installation, testing and commissioning from 11kv to 400kV. We provide integrated solutions, products and services on turnkey basis to our clients in the power sector. We have executed projects in all India basis & abroad also in difficult and challenging terrains and weather conditions.

Key highlights for EPC

- 400kV XLPE cable from NHPC Uri-II, 400kV XLPE Sorang project from Voith Hydro,

- 400kV XLPE cable Ukai project from LS Cable Korea,

- 400kV XLPE cable Bhamanoli project from LS cable Korea,

- 400kV XLPE Dahage project design work from Abengoa etc.

- 220kV XLPE cable Pragati Project from BHEL,

- 220kV XLPE cable DTL Project from LS cable Korea,

- 220kV XLPE cable DMRC project from J-Kumar,

- 220kVE XLPE cable KPTCL project from Brigade,

- 220kV XLPE cable AP Transco project from LS Cable Korea &

- 220kV XLPE cable KPTCL project from LS Cable Korea etc.

- 132kV XLPE Cable Bokaro Project from Siemens,

- 132kV XLPE cable HVPNL Project from ASI Glass.

- 132kV XLPE Cable AP Transco project from LS Cable Korea.

- 66kV XLPE Cable KPTCL project from Brigade,

- 66kV XLPE Cable DTL project from HTA,

- 66kV XLPE Cable Bosch project from LS Cable India &

- 66kV XLPE Cable TPDDL project from CCI etc.

- 400kV 200kV, 132kV, 66kV, 33kV & 11kV Jointing, Outdoor, GIS terminations works completed more than 85 Nos.

- Complete Electrification of Building (Internal and external Electrical Works) for Habitat Construction in Noida.

- Engineering, Procurement & Construction (EPC) contract for Indian Railways/IRCON for two package substations of 11kV voltage grade at Banihal, J&K at an altitude of 6500 feet on total turnkey basis which included design engineering, supply, erection, testing and commissioning of equipment procured from Schneider Electric.

- Supply and installation of 33kV and 11kV autoreclosers, including civil works, steel structure work, erection, testing, commissioning and remote automation for various industrial clients like Tissa Hydro Power, Ircon International, Alpla India, Dutta Daw & Co, Himachal State Electricity Board, Indag Rubber, etc., in Himachal Pradesh.

Our strengths

- EHV cables systems – Supply, Laying, Jointing, Testing and Commissioning on turnkey basis up to 400Kv.

- Package substations, Ring Main Units and Autoreclosers for transmission and distribution sector on turnkey basis

- Commercial LED lighting solutions on turnkey basis

- Cost-effective and efficient power equipment solutions.

- Transformer erection, testing, commissioning and preventative maintenance support.

Power System Training Simulator

It is a comprehensive Engineering Training System for the Power Systems Laboratory.

Power Simulation System: Our Power System is built upon free standing, mobile modules which can be operated separately, and one SCADA system module. Linked together, they constitute a complete power system and contain everything needed to teach and train students as well as engineers on how electrical power systems work – from Power Generation to Utilization. We undertake development of “Centre of Excellence” under Smart grid, which comprises supply,installation and training for three years.

The systems can be supplemented at any time with the other modules. The modular system will make it possible to arrange experiment scenarios covering real situations with a complexity designed and adjusted to the aims and knowledge level of the students. Adaptation to other conditions as well as partial upgrading is done fast and easily.The modules hold an advanced measurement system where each three-phase transducer comprises 20 parameters, where also non-symmetrical behaviour as well as cos phi are displayed. This extensive environment can also be studied on the SCADA – System.

Such facilities allow Power Utilities to give new Trainees necessary skills and experience before getting hands-on experience in Power Plants, Transmission & Distribution Systems. Our Simulation Systems give exposure of Emergency Situations under Safe Conditions to your staff.

SF6 Gas Purification, Quality Test and Leak repair

SF6 is a potent Greenhouse gas having global warming potential 23,000 times more than Carbon dioxide. We offer optical gas imaging leak detection cameras, indoor GIS Room monitoring ambient SF6 leak systems, so that SF6 leakages are pinpointed and rectified. We also offer SF6 leak repair solutions using patented curated resin developed by EDF and EPRI organizations. We are able to stop leaks using our repair solutions under charged/energized conditions. SF6 gas Quality has to be checked and maintained as per IEC and CIGRE standards (see IEC 60376, IEC60480, CIGRE B3.02.01). SF6 gas Analysis is offered by us for detecting 6 gas decomposition by products such as HF, SO2, Dew Point, Air, CF4 and overall SF6 purity.

The available technologies for SF6 Gas Purity analysis are Infrared Non-Dispersive, Acoustic/sound velocity and Chilled Mirror methods. We recommend CIGRE Brochure 676 on more understanding about the above technologies. SF6 gas is replaced by purifying it and by reusing it for GIS and outdoor circuit breakers. We use SF6gas Handling plants for evacuation of SF6 for removal of air and moisture for processing the Gas through filters and for filling gas in pressured components & for storing contaminated SF6 gas for future use after purification.

Transformer Online Moisture Removal System

Once cellulose is degraded to unacceptable level, it is considered that Power Transformer must be replaced.

According to World Leaders in Insulation Material Manufacturing, increase of water content in cellulose for 1% doubles the rate of its ageing.

Water in Power Transformers occurs from three sources:

- Water left from production

- Atmosphere water (Unmaintained Breathers and gaskets)

- Chemically created water by cellulose depolymerisation

Our solution is a dry-out unit designed for safe continual unattended operation on Energised Transformers.

Transorfilter via oil removes water from solid insulation. Cellulose drying process is gradual and non-invasive, so there is no risk of winding geometry change that would cause vibrations.

Even if a transformer is leak-free, and the oil preservation system is performing flawlessly, water is produced as a by-product of the Normal Cellulose Ageing process. We also offer highly effective treatment of insulating oil in transformer & other electrical equipment satisfies very high demands after only one passage through filters. We offer capacities from 1000-12000 litre/hour.

Partial Discharge Diagnostic System

It identifies, evaluates, and locates partial discharge faults in the cable insulation and accessories of all types of power cables. PD activity is an indication of incipient faults in the insulation and is widely regarded as the best early warning indicator. Partial Discharge (PD) measurement is a crucial procedure for assessing the condition of electrical systems. In fact, it’s one of the critical parameters evaluated during product manufacture, installation and normal operation. However PD testing was never

widely used as a powerful online diagnostic tool due to several limitations of traditional PD technologies. In fact, these technologies for online condition assessment of MV and HV assets used to be complex, expensive, unscalable to the whole asset, and nearly impossible to integrate with all key asset

parameters. In particular: traditional field-based technology for PD testing requires the electrical system to be switched off and connected to test equipment while diagnostics are conducted.

This procedure leaves the system idle for several hours during each test. In addition, they are often too expensive and complex to be operated by a non-PD expert, and defect detection and localisation can’t

always be performed online.

Traditional handheld ultrasound or acoustical instruments aren’t sensitive enough to detect and localise small but critical defects. Our wireless technology allows PD testing to be performed at a distance,

without the need for a direct connection to what is being tested. This means that measurements can be taken without having to switch the system off. And with a greater degree of safety for operators too.

GIS Partial Discharge Monitoring System

State-of-art PD monitoring System fulfills all requirements of a reliable PD pre-warning system. The GIS Monitor is a unique measurement system in the range of substation control and surveillance.The PD

Monitoring system is designed to conduct real-time online monitoring to detect and diagnose the incipient fault before they lead to catastrophic failure in power assets. The system is designed for Online PD Monitoring on rotating machines, transformers, cables, and especially GIS systems. The hardware core of the system has been fully redesigned and optimized for parallel, real-time PD acquisition on multiple channels. Any UHF signal can be detected and digitized within microseconds. A separation

of PD events from external disturbances or internal switching pulses is provided by the advanced software.

Each acquisition unit operates fully stand-alone to monitor all PD sensors in one GIS PD monitoring system in parallel.

A remote computer reads all data of the instruments via the high speed fiber optic LAN. The system comprises three components –

The Sensor unit detects partial discharge signals; the Data Acquisition Unit converts the signals measured by the sensor into

digital data; the Master Analysis Unit operates the software and creates a database. A separate noise sensor is available to eliminate noises.

Benefits and Features of PDMS:

- Real time simultaneous PD acquisition on all channels

- 24*7 Assurance that critical GIS Assets are performing correctly

- Application of Data Structure with PRPD Algorithm

- Noise Cleaning Band Setting through Band Pass Filter

- Eliminating External Noise by Gating Function

- Automatic Diagnosis of Partial Discharge caused by

- Neural Network Analysis

- Remote PD Monitoring using IEC61850 communication Protocol

- Partial Discharge Alarm Detection System Redundancy

- Sensitivity Verification of PDIX Sensor complied as per CIGRE TB654

PV Solar Systems

Off-grid

The presence of a functional electricity grid is not always as obvious as it would seem to be. An insufficient infrastructure is often the cause for an unreliable grid. Things become even more difficult when there is no grid at all. And yet you are in need of a reliable electricity supply. A local and properly functioning system is the only answer at this point. We offer you such an answer. We are proud to offer you our modern translation for freedom and independence. Energy, Anytime, Anywhere.

● DC Systems

In DC systems solar energy is converted into regulated DC. Consequently the regulated DC is fed to the batteries and consumers.

An inverter powers any AC consumers that are connected to the DC system. Unlike in DC systems, solar power is directly converted into AC

in AC systems.

1. DC consumers

A solar panel feeds the consumers practically directly. The only item in between the panel and the power consumer is a charge controller.

This charge controller controls the voltages for the consumers and the batteries.

2. AC consumers

This is a DC system with a 230 Volt output for AC consumers. In below example an inverter is added to provide the AC output.

3. Not enough sun – hybrid power

If the sun isn’t providing you with enough energy, a generator is added to the system. In this case an inverter/charger is used instead of an inverter. The generator is connected directly to the inverter. The inverter automatically regulates the starting and stopping of the generator, while maximizing the use of solar power and securing a long battery life.

4. Backup system

Solar energy can also be combined with a grid connection. But a grid that suffers from power failures in combination with an insufficient solar supply requires support of a generator. Below is such an example. This entirely automates the switching process between the grid and the generator.

● AC Systems

For larger solar systems that generally supply to AC consumers, it is more efficient to immediately invert the solar power into AC.

Therefore we call these systems “AC systems”. AC systems have a higher energy efficiency in comparison to DC systems. The PV inverter directly converts the solar energy into AC. This inverter requires ‘grid’, which is provided for by a powerful battery charger and inverter in one box. All excess solar power which isn’t used by the AC consumers is used to charge the batteries.

1. Island system with generator

As soon as energy is collected by the solar panels it is inverted to AC by the PV inverter. The generator supplies its alternating current directly to the inverter/charger. The Inverter will automatically start and stop the generator, while maximizing the use of solar power.

2. Solar and grid

In this backup system, AC from the grid can supplement the energy supply coming from the solar panels. And vice versa, the energy from the solar panels can cover any grid failure that may occur.

3. Solar, generator and grid

An extensive backup system such as the one illustrated here guarantees a non-stop supply of energy. If for example a grid failure occurs, the batteries are empty and at the same time there is a limited amount of solar energy available, the inverter/charger will start the generator. As soon as the generator is not needed anymore, it will be stopped automatically.

Distribution Management Solutions & Smart Distribution Systems

- Unmanned Substations (IEC 61850, IEC 60870-5-104 based comms over Encrypted, VPN, Underground and Pole mounted, Gas & Solid Insulated switchgear up to 40 KV), SCADA and other DMS system integration.

- Overhead & Underground network automation (Reclosers, Sectionalizers, FPIs, application specific FRTUs, automated Volt-VAR, SAIFI SAIDI improvement, CT Based LV Power Supplies for FRTUs etc.)

- Asset Management – Online/Offline Transformer Monitoring and diagnostics for Power & Distribution Transformers with Geospatial System Integration & applications.

- Advanced Communication Infrastructure – Unified Last mile and Backhaul communication solutions (2G/3G, 2.4 & 5.8 GHz., 865-867 MHz, Point to multipoint and Mesh) for Smart Metering (Electricity, Water & Gas), Distribution Automation, Street lighting, Video Surveillance etc.

- Renewable and distributed generation integration. Net Metering, Weather data and integration with SLDCs or upcoming Renewable load dispatch centers

- FPI Network Management: This can detect phase-to-phase faults, and phase-to-earth faults, active or inactive voltage, transmit fault info to control centre via RF/GPRS, provides Google Maps based locating service

- Autoreclosers and sectionalisers further add to the flexibility in switching between the overhead line feeders in case of faults.

- Smart Fuses or LT Autoreclosers: Protection of Transformers for Power Distribution networks along with clearance of intermittent faults and withstanding inrush current of transformers. Monitoring the fuses also helps in raising alarms.

- Power Quality Monitoring: Detecting Surging Voltage Levels & deteriorating power factor, timely compensation of voltage rises, correction of power factor, & harmonics filtering.

- Data Concentrator units for MDAS: For Data Acquisition, transmission and storage of metering Data from Consumer meters to Data centers, on request by Push Mechanism.

- Numerous Plug-in Options are available for connecting meters to downstream: PLCC, RS-232/RS-485/RF/Fiber Optic. Numerous Options for upstream communication are available too such as GPRS, Ethernet , RF etc.

- IOT based DTMS: Monitoring key operational parameters of DT for ensuring long service life, such as Relative Humidity and Temperature.

Emergency Restoration System

Electrical Transmission is interrupted when one or several transmission towers are damaged, causing a high economical cost for Utilities. ERS is a quick and efficient solution to temporarily replace the damaged towers,until the utility company can remove the damaged tower, build a new foundation,transport the new tower to the site and install it. Because of our knowledge partners and combining their expertise with our domain know-how about Indian conditions, we can do:

- Mobilization of manpower, arrange to transport ERS,ERS Tools and tackles to site in scope of vendors.

- Erection of towers to do by vendor in emergency after calamity comes or restoration of damaged circuits.

- Dismantling of the ERS arrangements including the line hardware conductors etc. after restoration of line on conventional towers.

- Transportation of ERS System and use the item of ERS arrangement back to storage location.

Using Our Systems, the transmission towers can be replaced in just a few hours by creating a by-pass and power transmission can be resumed much faster as compared to the other methods. All our systems are dimensionally compliant to IEEE 1070-2006.

Our ERS System are adaptable for all kinds of failure scenarios:

- Withstanding severe weathers conditions

- Heavy Lifting equipment not needed

- Adaptable to any configurations

- Capable to support high voltage line (765/400/220/132 KV)

- Usable in all types of Terrains

- Packaged for efficient storage and rapid retrieval

- Easy analysis software to design any structure types

Advantages:

- For Emergency restoration of power after storm or Natural catastrophe

- Construction of by-pass for damaged lines or various components

- Substitution of line sections for preventive/ corrective maintenance

- Quick installation of electrical power lines during constructional projects

Various Articles Required for ERS:

- Foundation Plate

- Rigid Gimbal

- 2.9 mtr Column Section

- 45 Degree/45 Degree Guy Plate

- Dead Ground Hardware Assembly

- OHGW Hardware Assembly

- Guy wire Assembly

- Anchoring Assembly

- Insulated Guy Wire Assembly

Online Intelligent Transformer Condition Monitoring (OITCM)

27% of all transformer failures can be traced back to bushing defects, and are also the main cause of Transformer fires. At the same time, the network requirements for availability and reliability of Transformers is increasing. Continuous condition Monitoring and evaluation of the bushings is hence imperative. Our Bushing Monitoring System diagnoses and analyzes leakage current in the bushing of a transformer in 1 microA, and then performs the real time diagnosis of insulation helping prevent failures in the bushing of transformers. Our system performs Bushing Insulation Diagnosis in the live line. The method of diagnosis is based on accurate voltage ratio measurement.

Ultra Precision leakage current measurement , along with automatic temperature calibration function effectively calculates Loss Factor (Tan delta) calculation. Additionally, the bushing state vector is derived from Voltage measurement for each phase. We can do diagnosis for EHV Transformer Bushing from 132 KV onwards. Our Dissolved Gasses in Oil Analyser is truly maintenance-free multi-gas Online DGA solutions based on proven near infrared (NIR) measuring technology.

Distributed Temperature Sensing

As per IEEE Guide to Temperature Monitoring of Power Cables, “Temperature is one of the most important physical data to be monitored for real time of Underground Cables. In fact, the cable conductor temperature should be known, with reasonable accuracy, at any moment in order to calculate the projected maximum current – carrying capacity (Ampacity) given by the operating and Ambient conditions.” DTS Instrument ensures gapless and real-time measurement along the entire fiber optic temperature sensor – either embedded in the wire screen or in the external sensor cable. The DTS System utilizes the Raman Effect to measure Temperature. An optical laser pulse sent through the fiber results in some scattered light reflecting back to the transmitting end, where it is analyzed. The intensity of Raman Scattering is a measure of temperature along the fiber. The position of temperature reading is determined by measuring the arrival timing of the returning light pulse similar to a radar echo.

Benefits of DTS Systems:

- Delivers valuable Circuit Monitoring Status Information to your Operations Team & Network Planners

- We do Fiber-to-Infrastructure mapping, so that one can pinpoint the location of the alarm. GPS coordinates can be stored for joints, manholes, HDD and splice locations.

- We measure Dynamic Cable Rating also known as Ampacity. The technique of measuring Ampacity is called RTTR. We allow your networks to operate at highest safe ampacity levels, at maximum loads.

- We can integrate with your SCADA system to ensure two-way communication.

- No Drift & No recalibration.

Transformer Diagnostic Van

Routine and advanced diagnostic tests can be carried instantaneously giving instant results.

There is no need to climb the transformer multiple times and all tests happen through automatic switching.

We offer Diagnostics Mobile Systems capable of performing all essentials tests in all-in-one system:Tan Delta Test,

Turns Ratio Test, Winding Resistance Test with PLTC, Magnetic Balance Test, FRSL Test, CT/VT Test, Demagnetization,

Circuit Breaker Analysis, Oil Breakdown Voltage, Sweep Frequency Response Analysis, Power Quality Analysis, Moisture

Content in paper of Transformer Measurement.

Cable Fault Locator Van

Cable Diagnostics Van is an all-in-one , Multifunction Cable Fault Location solution mounted in a Test Van.

All functions from insulation test, VLF, TDR, Reference Traces to the various cable fault methods such as

Arc reflection and IEC are controlled via a central control unit. It is equipped with the latest generation of

cable diagnostics in conjunction with powerful VLF testing technology. It is known as the world’s most modern and powerful cable test van system.

We help utilities operate reliable, safe and efficient power networks.

We have a rich experience in technical sales with a self-motivated and strong technical team.